-

Posts

200 -

Joined

Content Type

Profiles

Forums

Articles

Everything posted by shijan

-

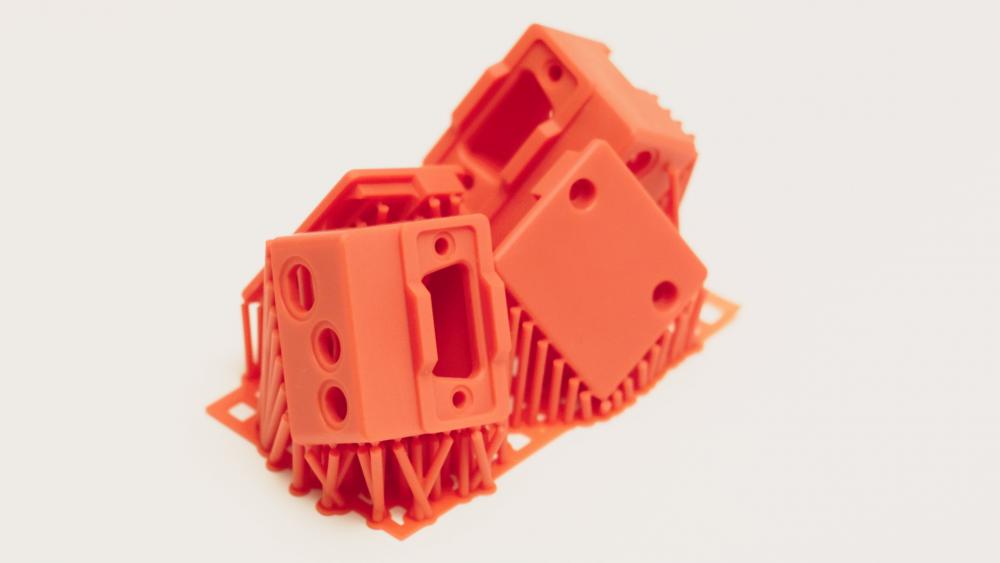

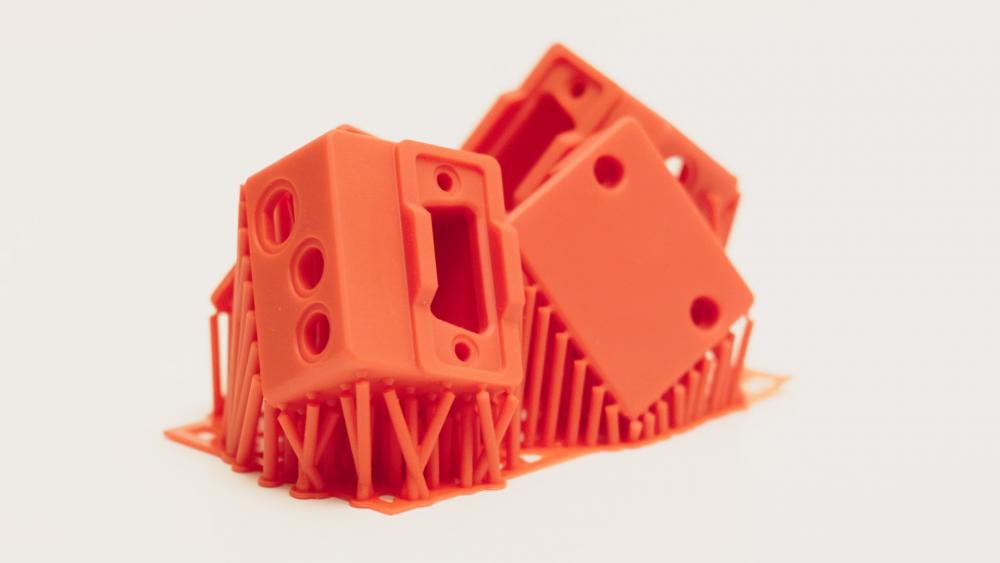

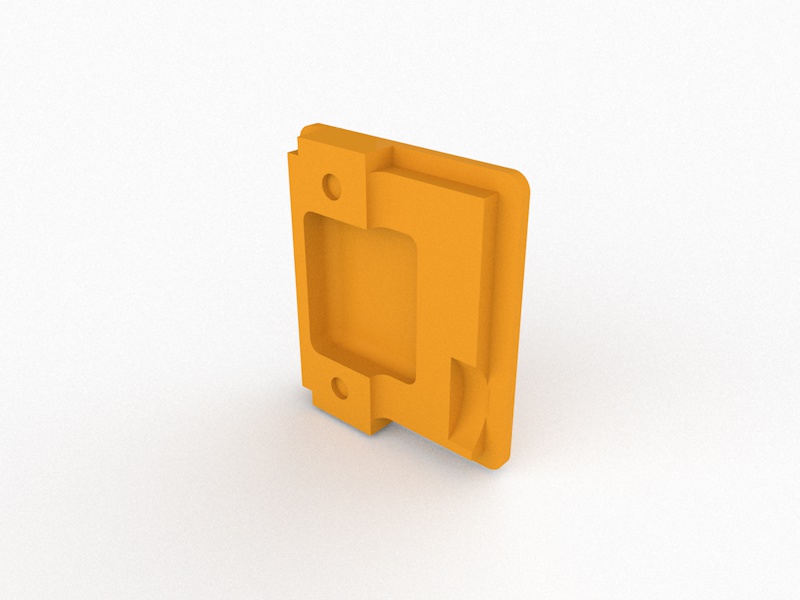

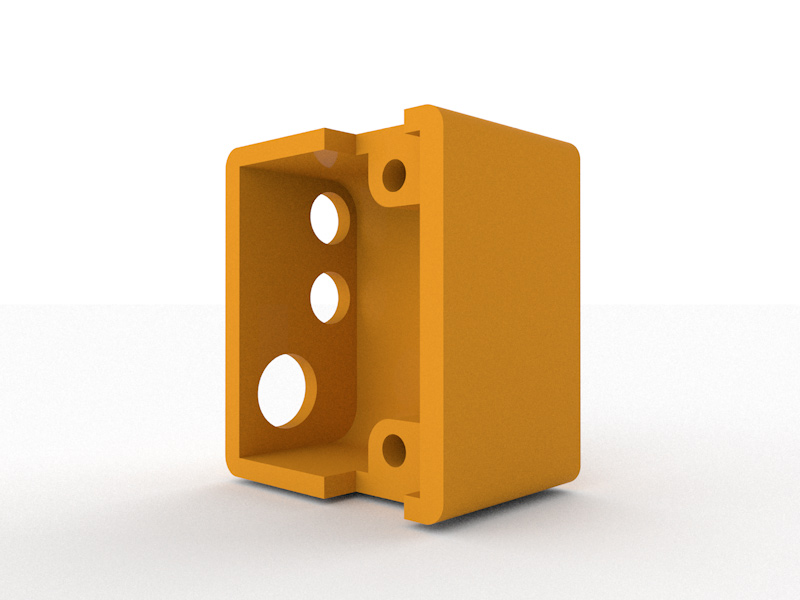

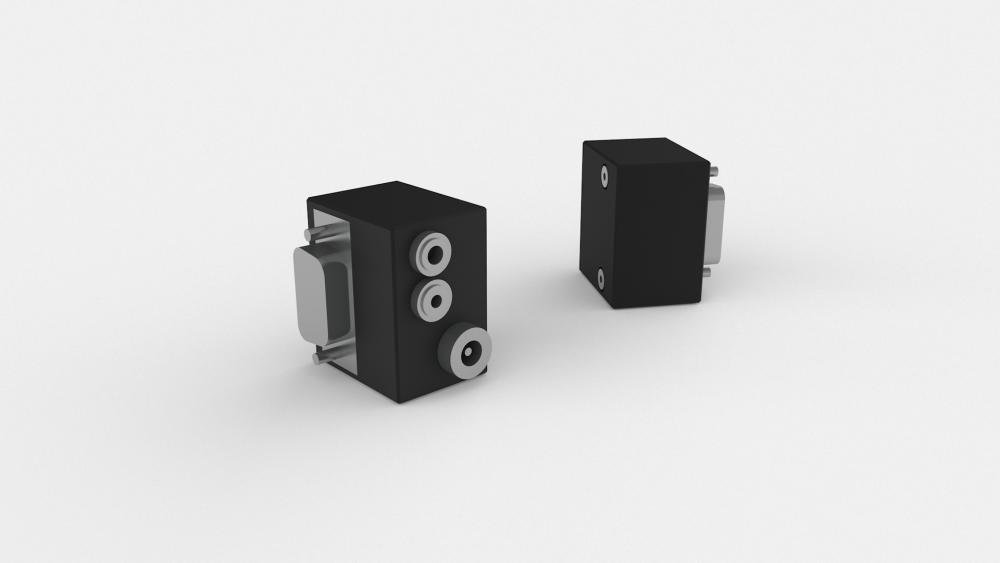

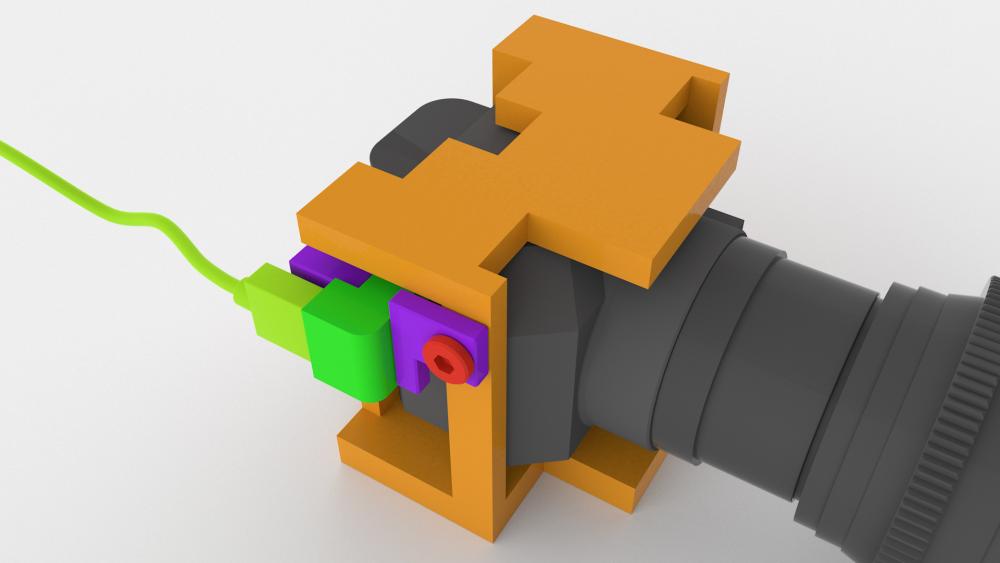

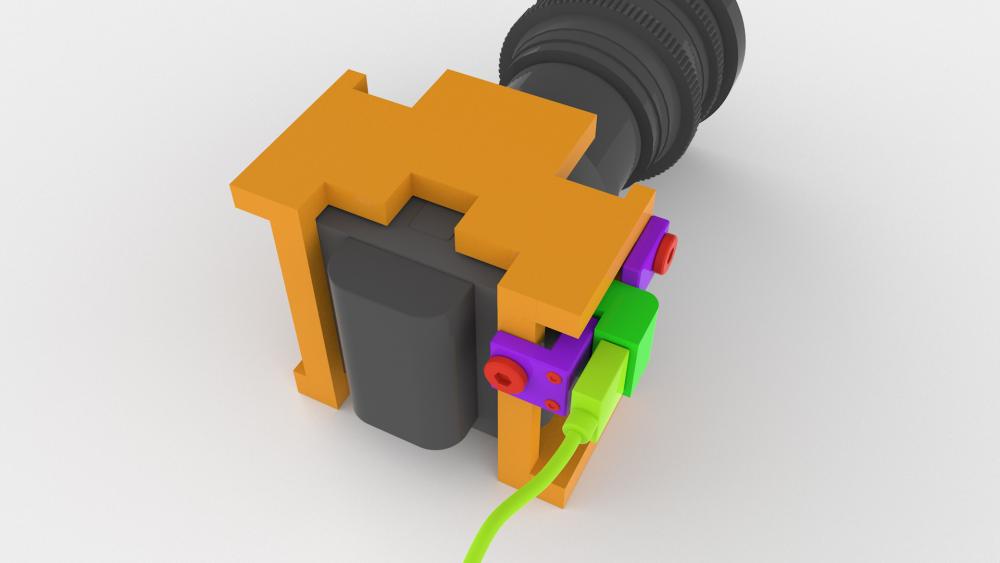

Got test 3D prints today. Box will be made from coPET (same material as used for water bottles manufacture). It is low shrinkage, resistant to impact loads (about 85 Shore Type D) and guaranteed usable in temps from -40 to +70°С. Done some quick sanding and install dummy connectors. Overall it is usable but after sanding surface became slightly grey. Probably the simplest way to get a uniform surface is to paint it with acrylic spray.

-

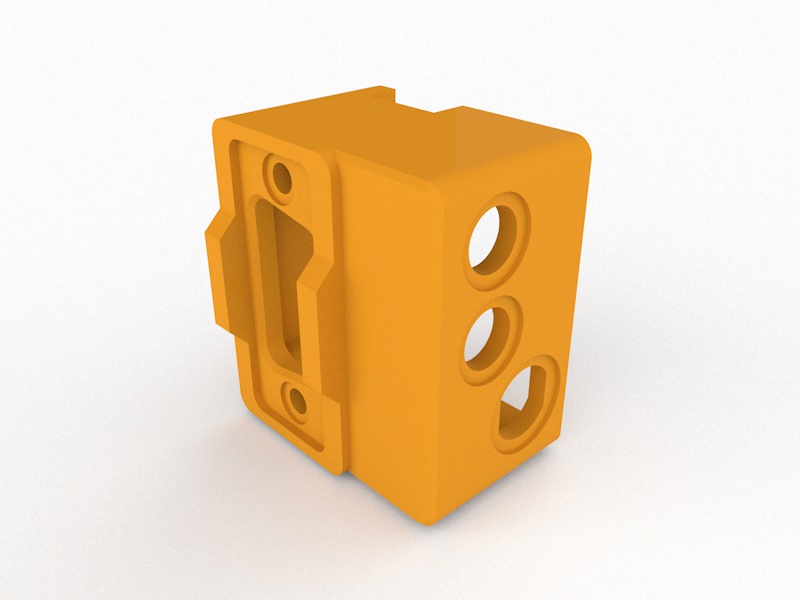

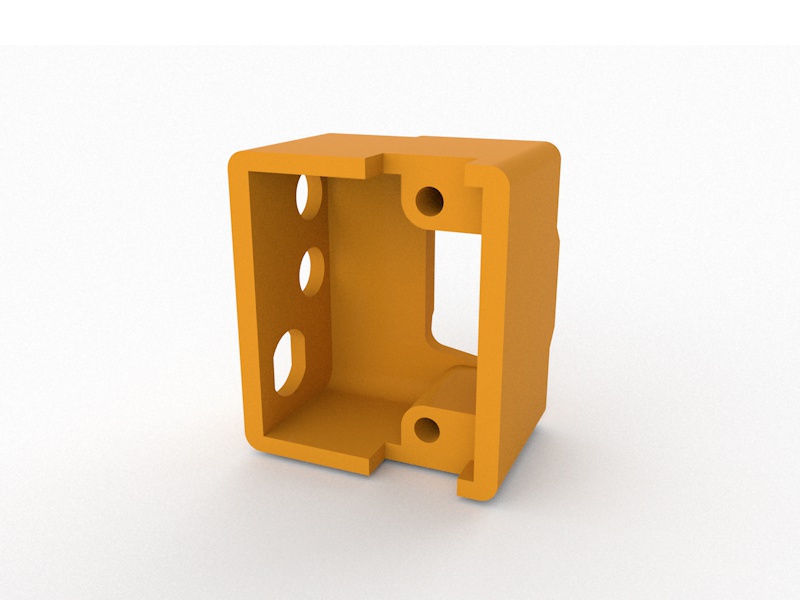

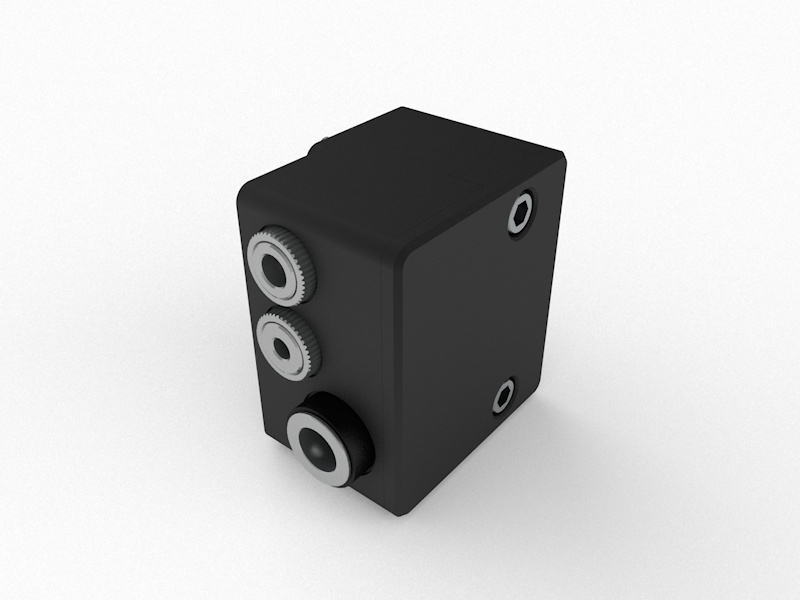

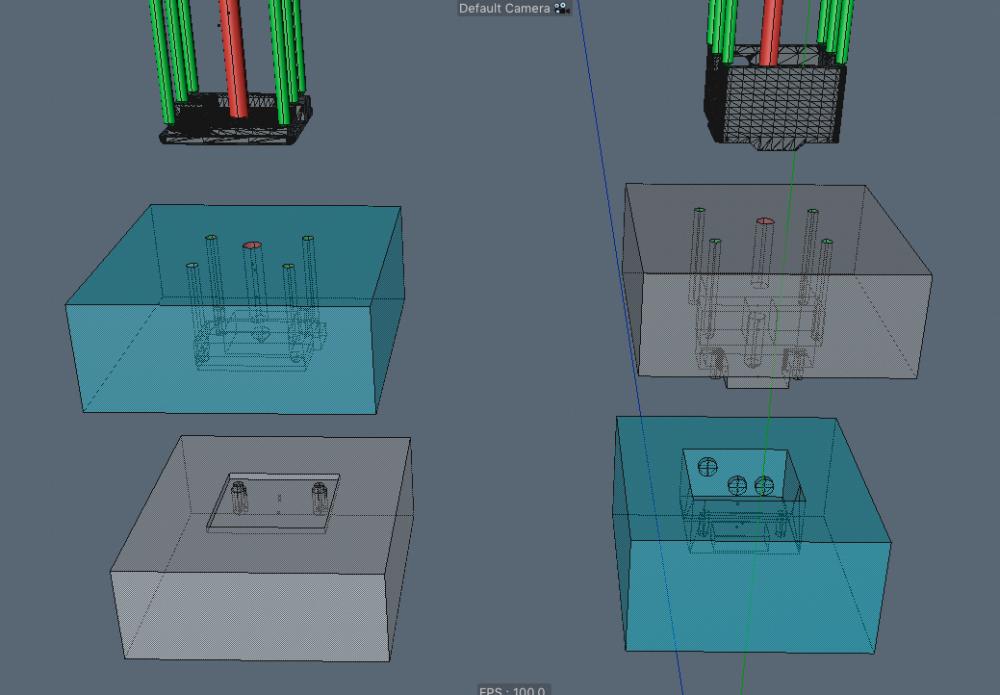

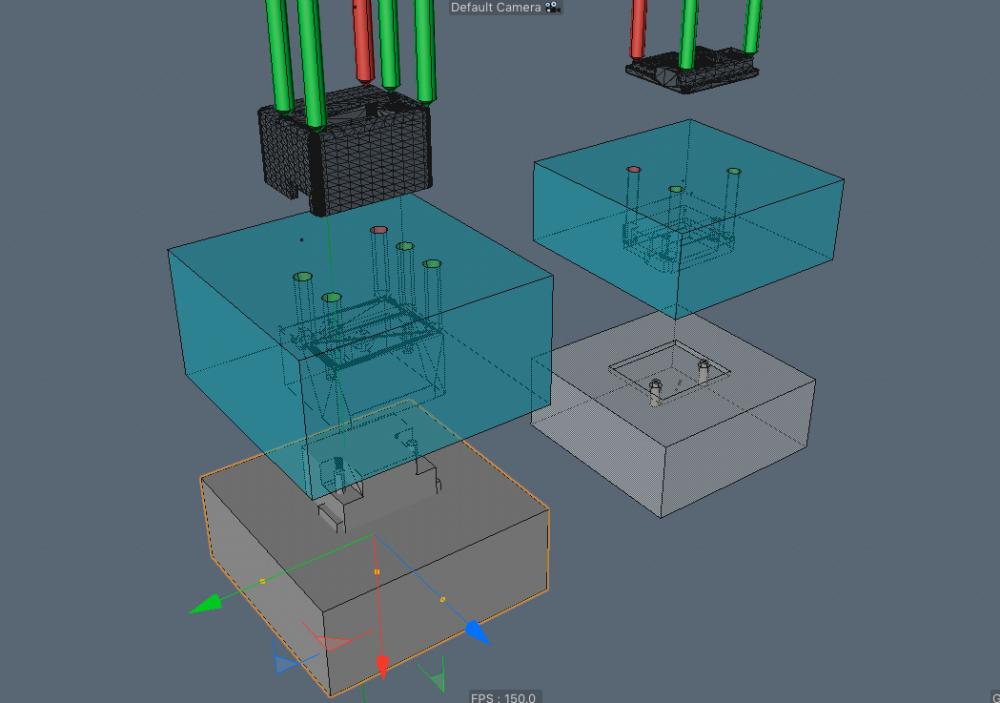

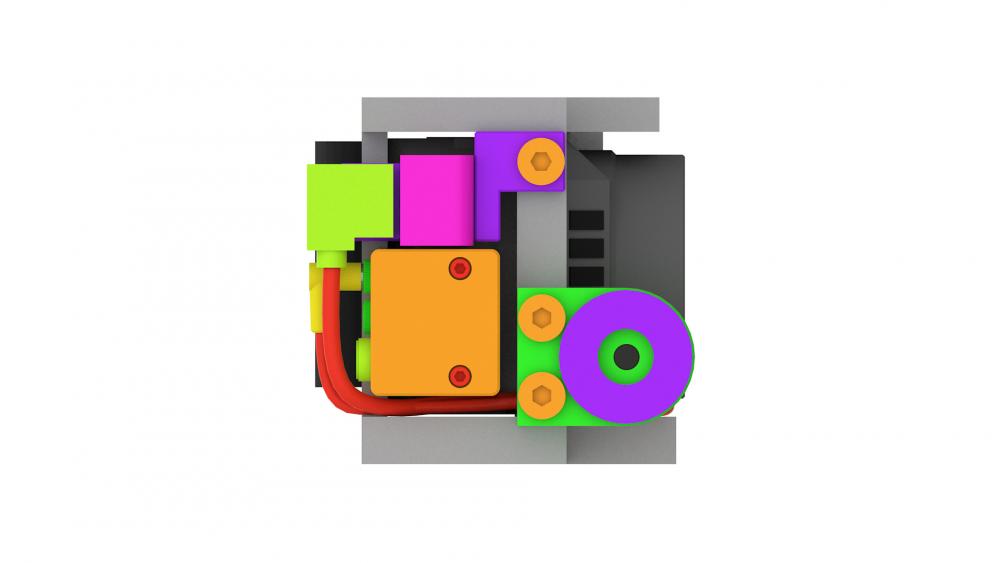

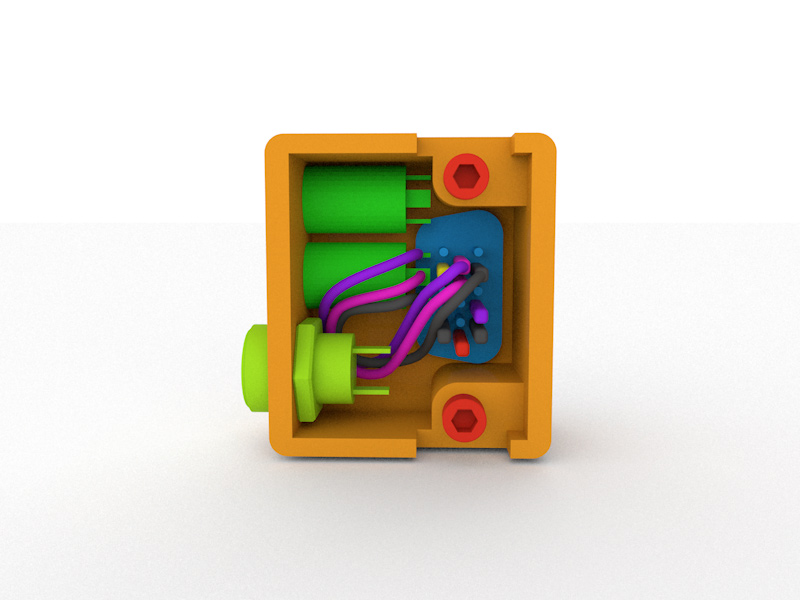

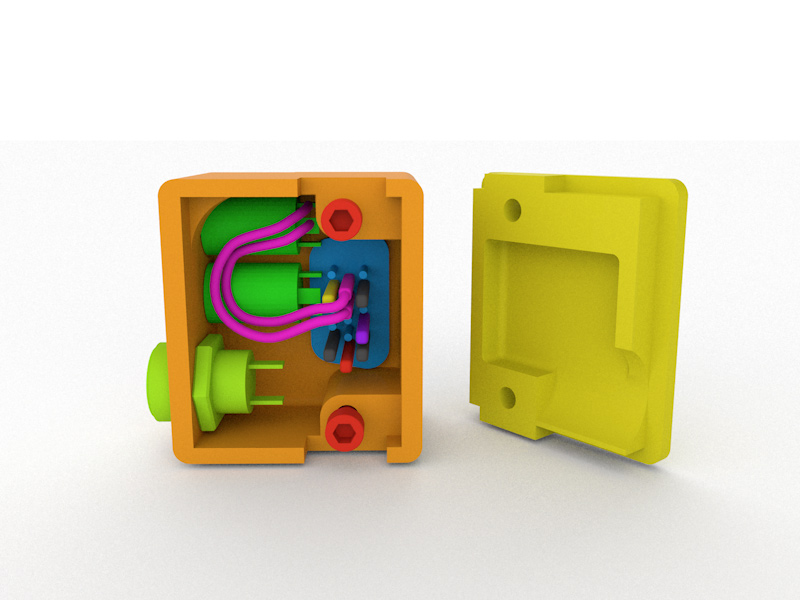

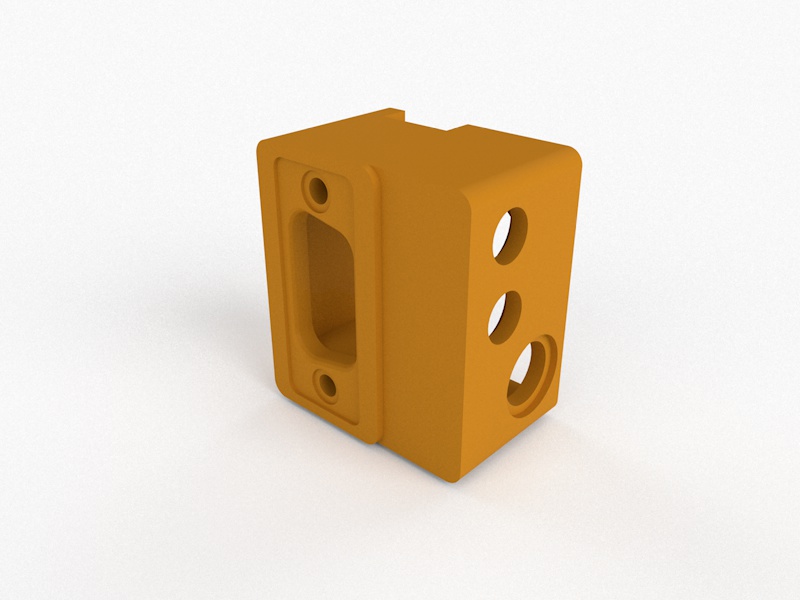

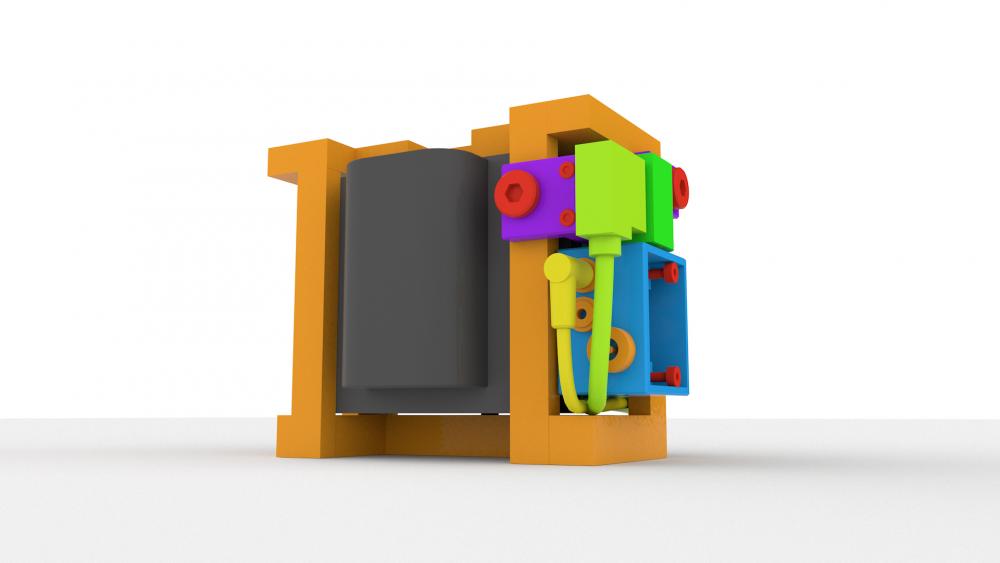

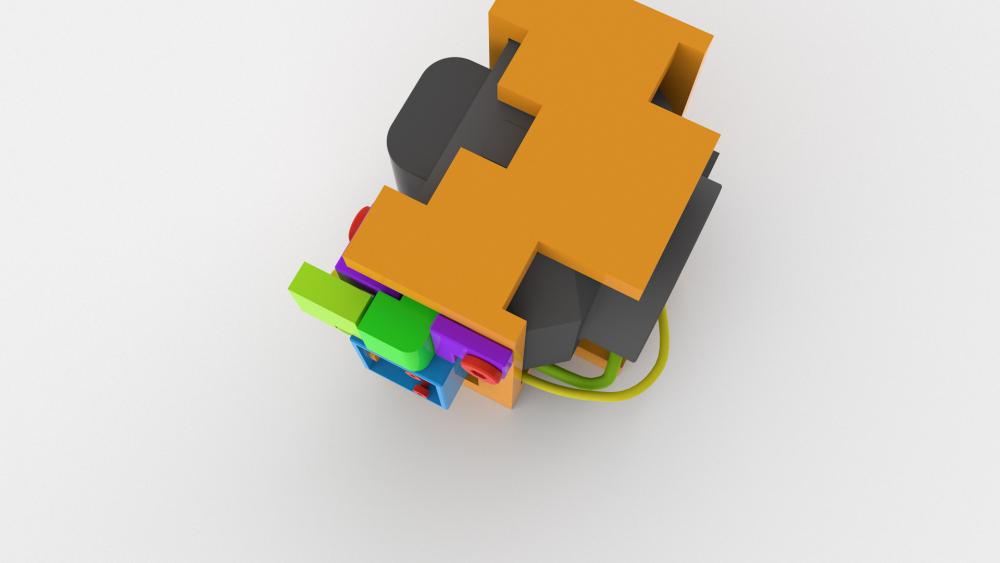

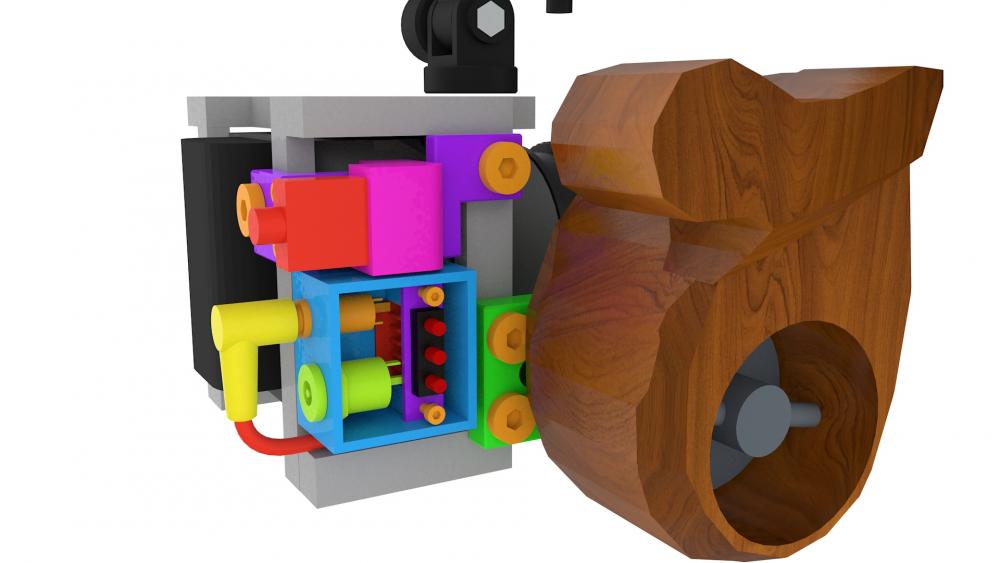

OK people, some news here: After long research i dropped the concept of DIY silicone molding and plastic casting because it appears too complicated, requires a lot of additional gear, results are not always predictable, and experiments may take many months. Also i find that those plastic casting materials are not too heat resistant and can deform under extreme sun. It is also problematic to get a neutral deep black color with them. So i return to concept of 3D printed box. I tested few different FDM 3D printers and find that they can produce very different results depending of used material and printer brand. Also instead of unpredictable fragile ABS plastic i find Elastan D70 - new industrial material developed by local manufacturer. It is solid but same time slightly elastic and resistant to impact loads (95 Shore Type D). Usable in temps from -40 to +120 °С. Resistant to UV light, X-ray, wet, oils, fats and many solvents, safe for food contact, low shrinkage durable material. Internal part of the box was also redesigned. It became much stronger now. In day or so i'll get a first test sample of printed box so we can see how it looks, how it feels and do a crash test with heavy hammer.

-

I want to believe that adapter will be available in the middle-end of the March. If someone potentially interested in this adapter just pm or email me and i'll add you to the customers list. This helps me to understand how many copies to produce in first batch and send them all together without delay.

-

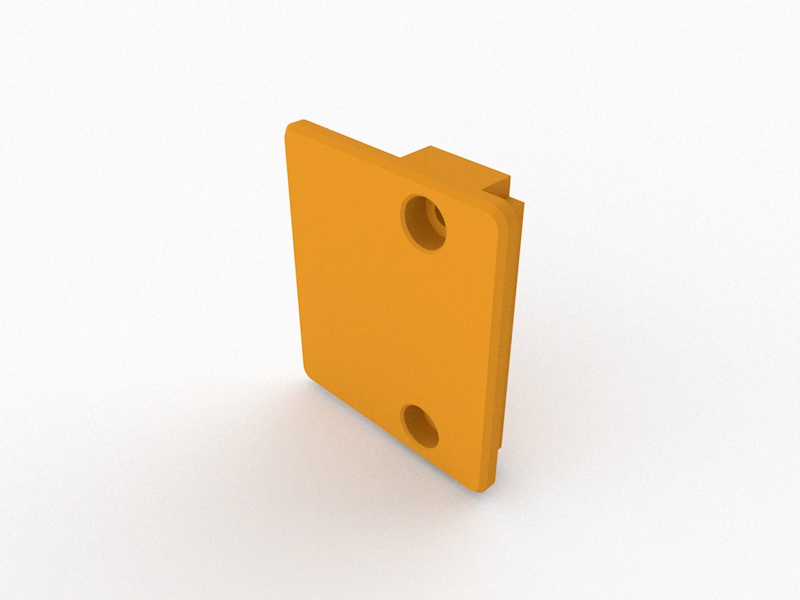

2 piece forms are more clear and precise and able to produce more copies before lose accuracy. Some holes are already closed inside to divide them for two parts for better molding. Nail sticks, nice!!! I want to make a matte finish, seems there are a some kind of spays that makes a little random drops on surface. Cameras bodies usually have this kind of finish. Some people tell me do not mess with SLA 3D Printer because it is not too precise for this size and needs a lot of post production. and suggest go for more expensive professional stomatology 3D prints. So i'm still thinking about it...

-

Those where really useful lessons! Got some feedback from one of the 3D printing labs few days ago. This is setup for Formlabs Form 2 SLA 3D Printer, kind of quality middle level printer but needs some hand work after printing. Also done sketch for molding layout today...

-

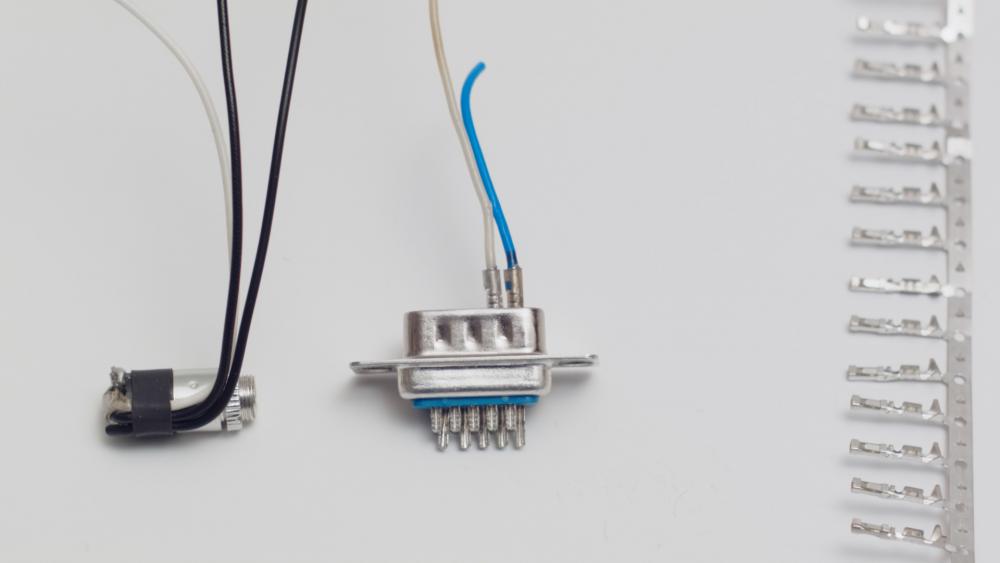

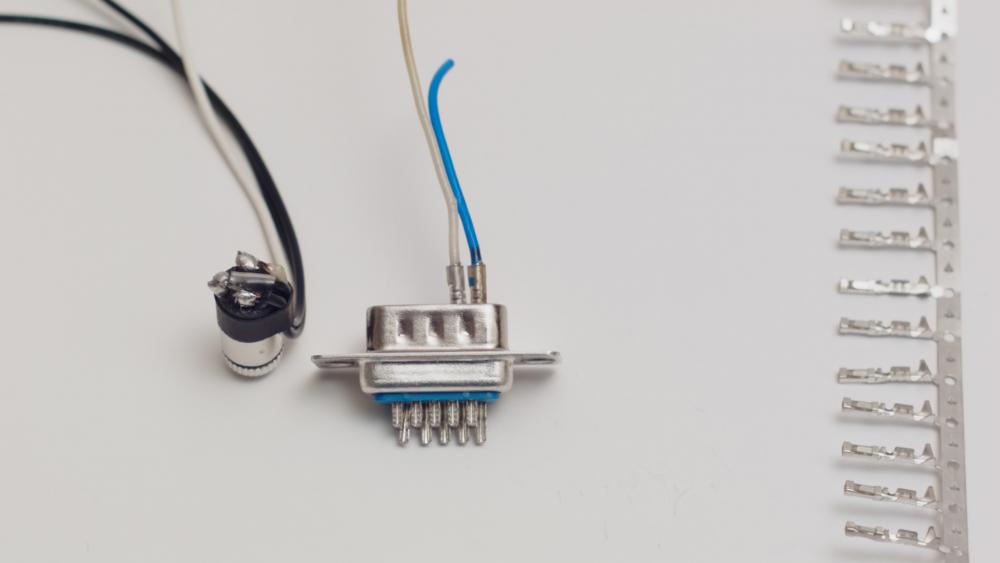

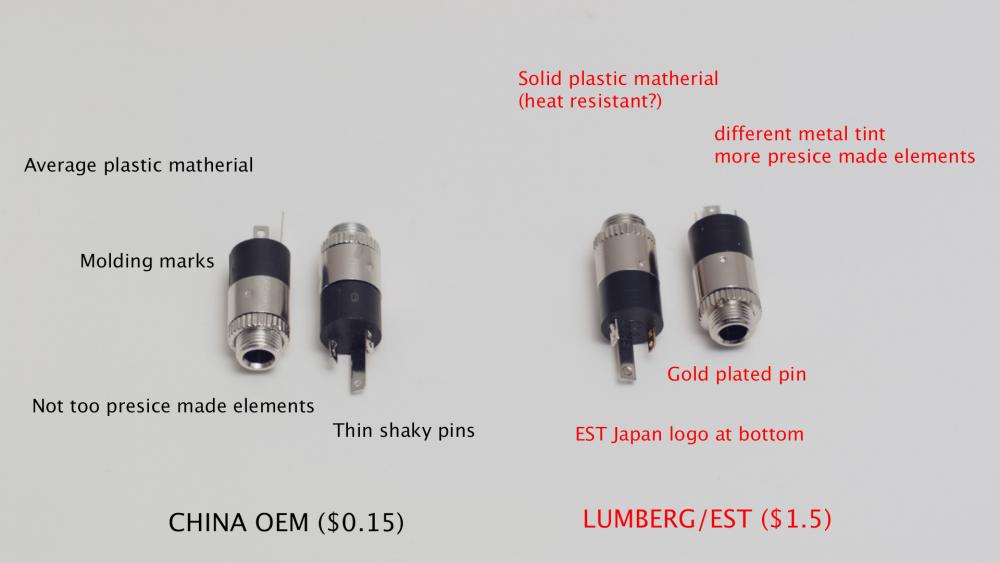

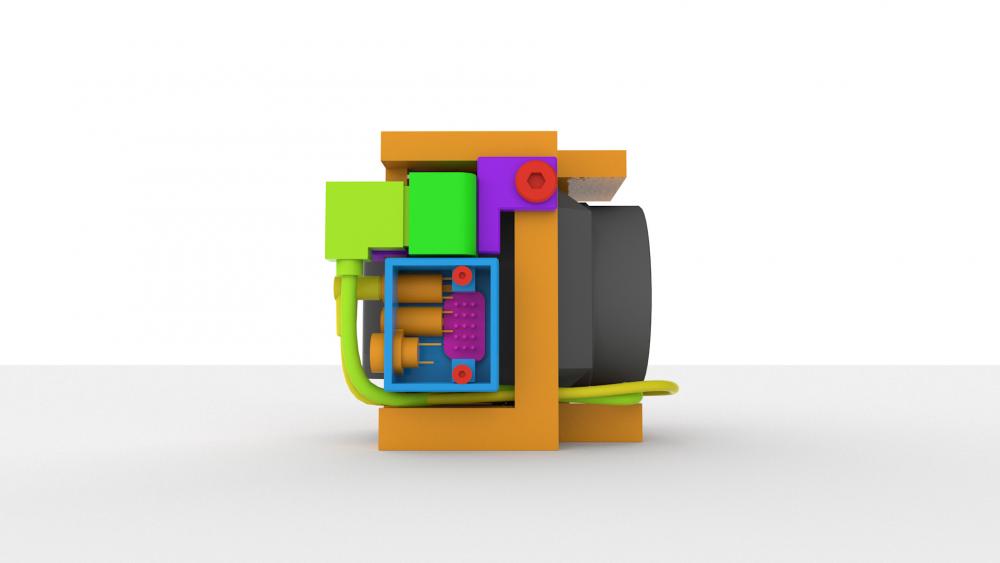

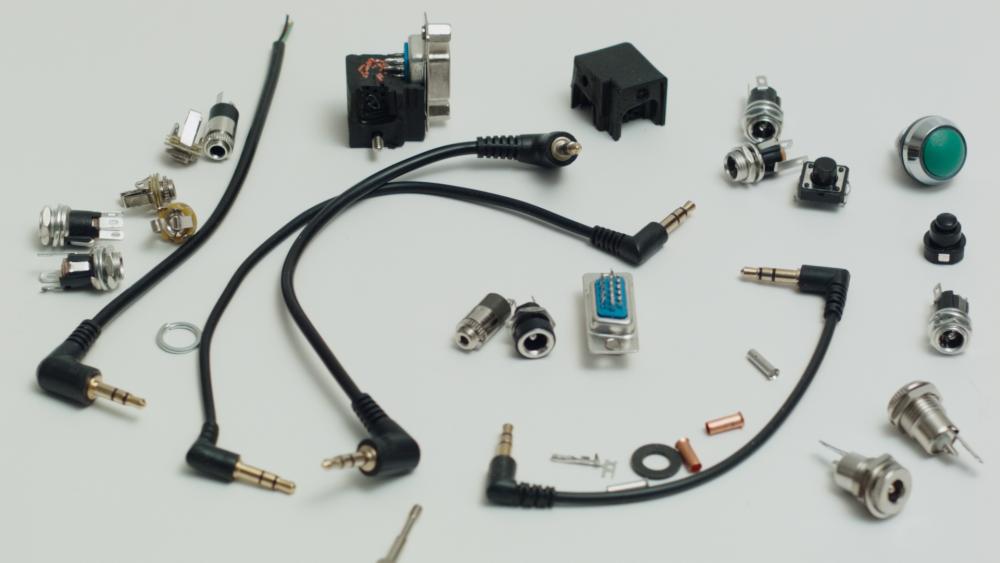

Was testing today different wires thickness and the way to solder them and confirmed that Dupont Jumpers warped with heat shrink tube will fit to VGA pins. Also done a little chart with Lumberg/EST vs OEM China connectors comparison. DC power connectors are also different. I can't find a Lumberg DC power connectors in local stores yet, but already find another brand which is better quality than OEM.

-

Yea, i was thinking about that additional corner too and made some redesign in the evening. It appears that it is not possible to manufacture this with regular CNC machine because there are few triple inner corners which impossible to mill with regular tools. So yes, it will be molded, i have a friend who makes things with same technology every day. Master copy will be 3D printed on hi end printer anyway. Sure it is way more expensive than usual 3D printing, but for one copy it is ok.

-

Currently i search a better way to manufacture a body of the box. At this Sunday my friends made test samples on usual FDM 3D printer and i don't like the results. It appears not too precise and material not strong enough for this kind of small things, also it takes too many time for batch manufacture. So i refuse my idea of simple 3D printed body. Now i got few other more precise and professional manufacture options, like DLP/SLA 3D printers or CNC machined body sample for future molding. Need to test that things too. Also i find a solution for more flexible pinout. Everything will be connected directly to D-sub pins with tiny Dupont Jumpers. Anytime you can just open the box and change pinout for example from S.bus to PWM or to anything you want.

-

Yep, I also expect this problem and can't find a solution. I made temporal DIY mount http://www.eoshd.com/comments/topic/20153-the-simplest-bmmcc-rig-ever-made/?do=findComment&comment=163917 Also i co-designed adapter with SmallRig but version to they do it huge and bulky, targeted for heavy monitors http://www.smallrig.com/SMALLRIG-DSLR-Monitor-holder-Friction-Mount-Kits-1842.html i'm tied to prove point of view that people needs more compact things sometimes. Also you can try to DIY experiment with HotShoe or microphone mounts or light stands mounts. People use them as monitor mounts too. Also here is nice stand https://cinegearpro.glopal.com/uk-UA/p-8865859341/dof-micro-cold-shoe-mount-ball-head-for-camera-top-accessory.html?utm_campaign=en_GB&utm_medium=pr&utm_source=www.cinegearpro.co.uk Not sure if it is just rebranded China model something like this https://www.aliexpress.com/item/Camera-Tilting-Bracket-1-4-Screw-Hot-Shoe-Mount-Adapter-for-on-Camera-Led-Video-Light/2038197621.html or https://www.aliexpress.com/item/1-4-Screw-Mini-Hot-Shoe-Ball-Head-Flash-Bracket-Holder-Mount-Screw-For-Camera-Tripod/32605794972.html?spm=2114.30010308.6.7.7hi7J6&s=p or if it is something originally designed Also i don't like that all that mounts are made from plastic. This makes them too shaky even with lightweight monitors. Also you can try to get a metal GoPro mount with 1/4" screw on top if your monitor is really small.

-

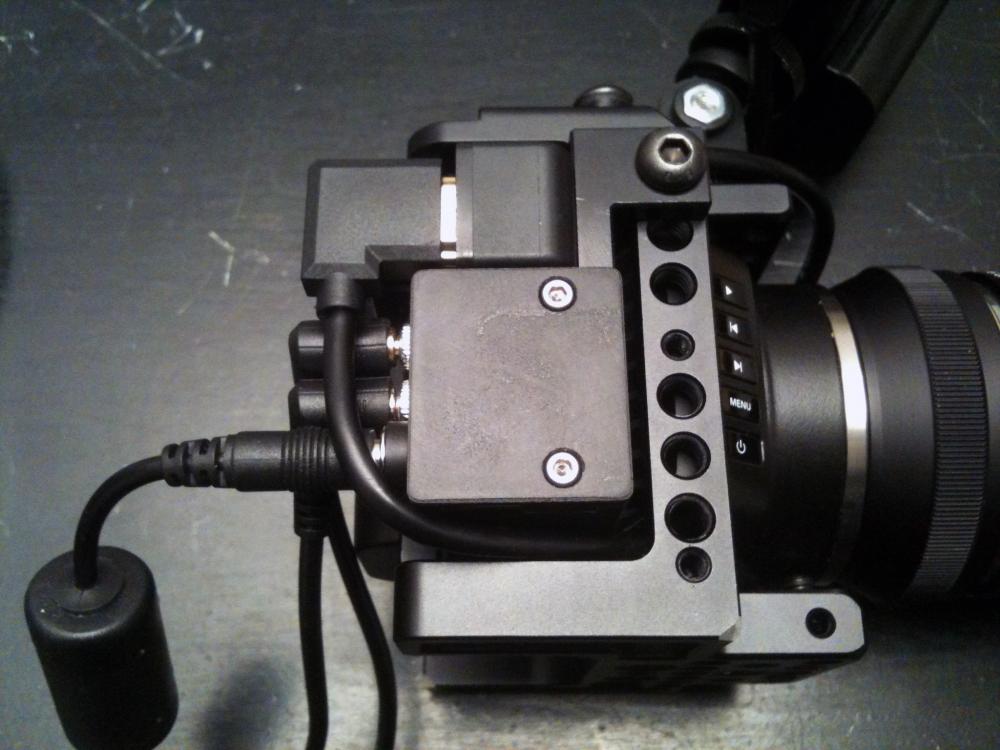

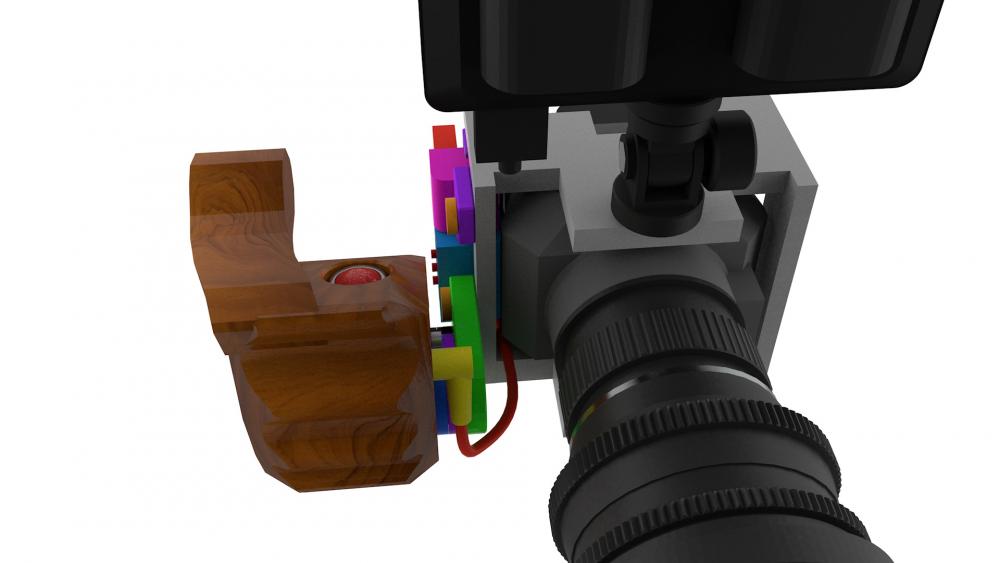

Hi there! As you may know i'm a developer of Angle HDMI Clamp Kit http://www.eoshd.com/comments/topic/21377-angle-hdmi-clamp-kit-for-bmmcc-smallrig-cage-and-ugreen-angle-hdmi-adapter/ and co-designer of SmallRig BMMCC cage. My next attempt in this line of projects was the camera handle, but it seems things moving slowly and i decide to release Angle Expansion Box Module first. Box uses high quality connectors made by Lumberg (Germany). It takes months to test a lot of different connectors before choose proper ones, especially DC power which should work smoothly with BMMCC power plug same as with another more simple ones. Angle shape provides compact and secure cable management, no more mess of wires around camera. Fits perfectly to MBAngle HDMI Clamp Kit size and shape. 3D printed body. Compatible with SmallRig and Wooden Camera cages. Compatible with other BMMCC controllers. For request 3.5mm jack can be wired to 2 PWM channels or to S.Bus. Other connectors are 2.5 jack LANC and camera DC power in. Currently this project is in final stage of development. Hope expansion box will be available in month or so. Price will be around $25-$50. Worldwide shipping with registered air mail about $5.

-

Yes, maybe there is a reason to experiment with less stronger filters (80B or 80C). Also maybe i do a test with warmer light source closer to 2800K to see how it works. Beside different saturation I notice only only chroma noise difference in some colors, it can be easy fixed with noise reduction or chroma blur. BTW these test images are with chroma noise reduction applied, thats why the color patches are pretty clear as you can see.

-

if someone still interested, here are two frames from my early tests of BMMCC done with Hoya UV-IR filter+Hoya 80A and with Hoya UV-IR filter only. As light source i used 500W halogen lamp. In Resolve i adjust WB by the grey Color checker patch (third from the left). Color conversion done with custom generated LUT in LUTCalc app (output gamma Alexa-X-2, output gamut LC709). To my opinion 80A filter makes some things better but it is not too perfect. It rises color temperature but also adds cyan-green tint to the image which eats saturation in greens when you try to adjust image to netural grey balance. As opposite warm temperature light souse without filter produce very low saturated and noisier yellows for same reason. Probably all those color shifts can be corrected with more complicated color correction but this is another story...

-

For tungsten use RAW and get 80A filter. The only side effect is that you loose 1 stop of the light with it. Without 80A filter even in RAW you loose a lot of color information, washed and shifted colors if balance back to 5600 white point.

-

How about Pentax Cosmicar f/1.8? Its inexpensive and 12.5, 25 and 50mm covers 1" sensor and they also have f/1.4 versions too. On ebay sometimes can be found earlier versions of same lenses for about $40. And this lens needs some modification because it cant't fit properly to c-mount adapter. https://www.bhphotovideo.com/c/product/979788-REG/ricoh_c21228kp_b1218a_monofocal_manual_iris.html https://www.bhphotovideo.com/c/product/979790-REG/ricoh_c22516kp_b2518_monofocal_manual_iris.html

-

just find a very nice 0.5m angle HDMI cable as add-on to my angle adapter kit. This makes things even more compact and more secure. Now i can put camera to the bag without risk of damage cable or HDMI connector. Recommend it! http://www.ebay.com/itm/NEW-HDMI-CABLE-V1-4-1080P-GOLD-PLATED-CONNECTOR-BLURAY-3D-TV-DVD-PS3-HDTV-XBOX-/272486622073?var=&hash=item3f7177e379:m:m823GMKeVGgsQcKw_9aBzdQ

-

HDMI clamp kit is finally ready to ship! So discussion and feedback about it moved to new thread

-

-

HDMI clamp was slightly changed after some testing and now it looks like this. Also if someone interested i decoded to produce a small batch of those clamps for sale. It is factory machined with high precision. Tested, works great! PM me if you interested. The price is in range of SmallRig clamps. Inexpensive shipping worldwide in small packages.

-

-

One more small improvement. For extra durability added four 1/4-20*3/4 GRUB SCREWS around the lens mount. Screws coated with heat shrink tube sleeve around the end. Also added one 1/4-20*5/16 GRUB SCREW to fix camera at the top of the cage.